Dec 13, 2021

Specialized Farm Laborers are Instrumental to Run Vertical Farms

Harbor Farmz’ vertical farm in Michigan

Editor’s note: The following information is derived from an interview between Agritecture and Jerome Doucet, CEO, and President of Montel. As there is not enough data in the industry to compare labor safety in vertical farms with conventional soil-based farms, neither Agritecture nor Montel can claim that vertical farming is safer for farm workers with clear evidence.

What would you say is the most crucial component of a vertical farm?

Is it the vibrant LED lights, the automation maintaining complete environmental control, the rows and rows of crops stacked on top of one another, or something else?

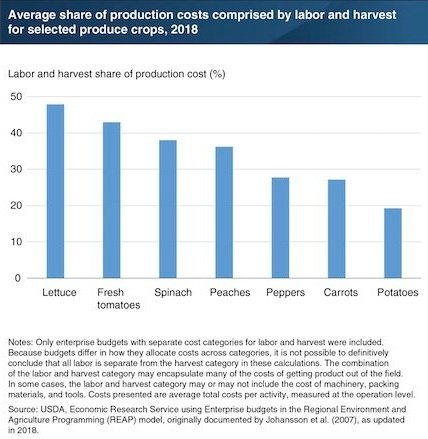

Chart showing the average share of production costs comprised by labor and harvest for selected produce crops in 2018. Chart sourced from the USDA Economic Research Service

As one of the most overlooked aspects of this popular farming method, labor is shockingly the largest expenditure for all crop farms on average.

As proof of this, in their 2019 United States Total Farm Production Expenditure Report, the USDA’s National Agricultural Statistics Service calculated that labor costs U.S. farms $25.4 billion (14.0% of their total expenditures) that year.

Additionally, according to the Center for Immigration Studies, labor costs comprised only 6% of the price consumers paid for fresh produce in 2007. This means that of the price consumers pay for their produce, very little indeed goes to the farmworkers behind the operations.

As is seen in the Australian agricultural market, this can be owed to the fact that around 67% of farmworkers are primarily paid by an hourly wage, with 33% paid using piece rates (a fixed rate for each unit produced).

Besides underpaying laborers, traditional agriculture is said to be one of the most hazardous industries to workers. According to the CDC’s National Institute for Occupational Safety and Health (NIOSH):

GoodLeaf Farms in Ontario

410 farmers and farm workers died in 2019 from work-related injuries, resulting in a fatality rate of 19.4 deaths per 100,000 workers.

Each day, roughly 100 agricultural workers suffer a lost-work-time injury.

In 2014, an estimated 12,000 youth were injured on farms. Four thousand of these injuries were due to farm work.

It’s important to note that the agricultural industry suffers from a lack of reporting and undercounting of injuries and illnesses. Thus, these numbers are, in truth, higher than reported by federal agencies.

Such concerning statistics have led to the Occupational Safety and Health Administration claiming farmworkers to be “at high risk for fatalities and injuries, work-related lung diseases, noise-induced hearing loss,” and more life-threatening conditions.

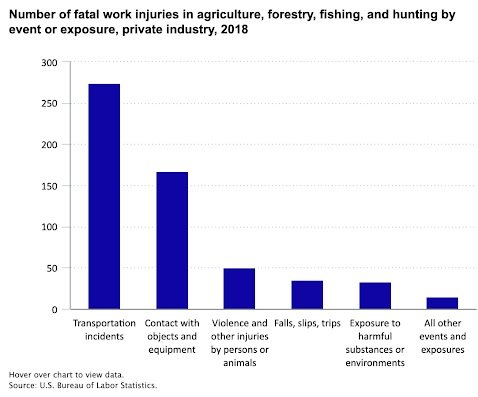

Chart showing the number of fatal work injuries in agriculture, forestry, fishing, and hunting by event or exposure in the private industry in 2018. Chart sourced from the US Bureau of Labor Statistics.

While eating our fresh vertically-farmed produce, how often do we stop to think about the hands behind the agricultural operations?

Let’s dive deeper into the data.

Reports from the US Bureau of Labor Statistics indicate that the two most significant injury categories are ‘transportation incidents’ and ‘contact with objects and equipment.’

As the President & CEO of an organizational storage system and grow rack system company, Jerome Doucet highlights that “if we intend for the agricultural industry to keep growing and feeding our ever-growing population, we need to stop overlooking labor treatment. We need to ensure greater workplace safety and productivity while enabling more worker wellbeing. Vertical farming can help us achieve this goal.”

The right equipment and specialized workforce enable greater human safety, food safety and overall productivity.

Harbor Farmz’ vertical farm in Michigan

Doucet adds that “by increasing automation and reducing the need for lengthy transportation, Montel’s stationary and mobile racking enables vertical farms to increase productivity while minimizing manual labor and injury-prone activity.”

This creates the need for specialized labor, redefining what it means to be a farmworker. Employees of vertical farms tend to receive full benefits and living wage salaries.

The fact that there are no open fields susceptible to pests, bird droppings and animal encroachment increases food safety in vertical farms and allows farmworkers to have better working conditions than on-the-field agricultural jobs.

“By working in climate-controlled environments, farmworkers are no longer exposed to toxic chemicals, reducing the rate of illnesses, and supporting increased productivity with fewer sick leaves needed.”

Montel’s stationary and mobile racking systems benefit both farmworkers and farm-owners with their increased productivity and safety.

Doucet shares that “while there’s no need to bend over to seed or harvest crops in vertical farms, this process can still be made more efficient to avoid transportation and equipment injuries.”

A good example here is static rolling benches that are often used in greenhouses. “These conventional benches are fixed to the ground, so they’re not mobile. The bench on top can typically only roll eight inches and a half from the center. So, there’s not a lot of flexibility, and there are very narrow aisles,” giving little room to farmworkers to perform tasks.

In contrast, “Montel’s mobile grow racks have a push button on the core of the handle that locks any mobile unit from moving. This acts as a safety device, preventing possible injuries. Montel’s mobile racks can also create wider aisles, so you have more freedom and more room to work with the plants and at the same time you enhance in-aisle workflow and you also increase labor productivity.”

One of the most significant factors to examine is the “cost of access.” This refers to the time spent getting to crops - whether this is walking between aisles to tend to crops or riding scissor lifts up and down rows of plants to harvest them.

Agropod’s R&D Center in Quebec

Montel’s mobile racking systems help you minimize this cost of access. “Instead of having one aisle, you can have two or three. Growers want to fit in more, and that’s what our mobile systems help them achieve. With conventional static racking systems, you're wasting space. Mobile racking helps you make use of every inch of space so you can grow more with less while reducing travel time between rows of crops.”

Additionally, while scissor lifts and rolling scaffolders address productivity in vertical farms, they can be an injury risk. “Montel’s grow racks respond to these concerns by being ADA compliant, fire protection compliant, and in compliance with OSHA, to ensure farmworkers can access higher tier crops safely.”