Feb 8, 2022

Using Cyanobacteria to Lower Farm Emissions

Editor’s Note: This is an investigative article from Agritecture’s Agriculture Technologist Justin Hyunjae Chung, and Food Systems Consultant Christian Kanlian, on organic fertilizers and the replacement of the Haber-Bosch process. The following information is derived from an interview between the Agritecture team and Lior Hessel, CEO of Growponics.

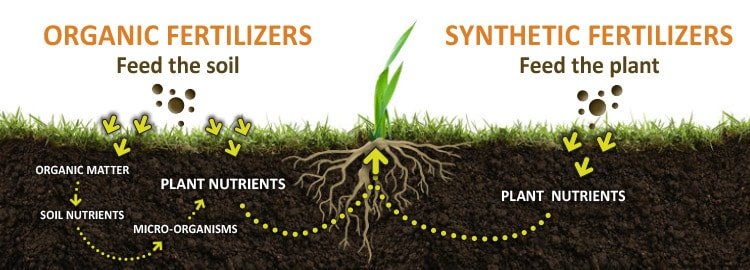

Fertilizers have been used to enrich the soil that has supported human life for millenia, but not all fertilizers are created equally. Made from organic matter, natural fertilizers gradually feed an extensive network of insects and microbes that in turn make the nutrients available to our crops, while synthetic fertilizers are highly concentrated and quick releasing, bypassing the microbial transformations.

Graphic explaining the differences between organic and synthetic fertilizers; Sourced from Milorganite

Although quick to work, synthetic fertilizers do little to develop strong root systems and the long-term fertility of soil. These blends are also highly concentrated and water-soluble, which can lead to ecologically damaging run-off through a process called eutrophication. Switching to a recirculating hydroponic system can help address this problem, but finding a high-quality, organic, soluble fertilizer continues to elude growers.

Nitrogen & The Haber-Bosch Process

Nitrogen, which is the element most needed by both plants and fertilizer companies, is sourced synthetically through the Haber-Bosch process. The process “fixes” atmospheric nitrogen into a form usable by plants and is ubiquitous in our modern world. In fact, it is estimated that nearly 80% of the nitrogen atoms found in our body originated from a lab using this process, having traveled through soil, plants, and the food we eat.

The world’s first Haber-Bosch plant (BASF), located in Germany; Image sourced from BASF

Despite its popularity, The Haber-Bosch process has staggering environmental impacts and requires immense amounts of energy. Globally, the process generates 1.5 billion tons of carbon dioxide emissions each year, approximately double the total carbon emissions from passenger vehicles in the US.

Although CEA operations like to tout the environmental benefits of recapturing water and reducing food miles, the significant energy requirement of the fertilizers that enable this efficient growing process rarely gets the attention it deserves.

Introducing Growponics

Lior Hessel, CEO of Growponics, at one of his facilities; Image sourced from Growponics

Over the past decade, Lior Hessel, CEO of Growponics, saw a major shift in consumer demand for organic produce, and realized that we couldn’t truly build a more sustainable food system without addressing the global emissions of fertilizers. Hessel shares that while “people want organic certification [in hydroponics], the organic fertilizers that are currently available are not good enough - solid organic fertilizers cannot be applied to hydroponic and other fertigation systems and the available liquid organic fertilizers cause a 15-20% reduction in quality and yields.”

Growponics tackles this problem head-on by attempting to replace the Haber-Bosch process through harnessing the power of cyanobacteria, which are among the oldest photosynthetic organisms on Earth.

The team has engineered a photobioreactor to utilize cyanobacteria’s natural biological process of fixing atmospheric nitrogen (N2) into ammonia (NH3), using the sun as the only energy input. They then refine the ammonia into a nitrate-based (NO3) hydroponic fertilizer.

Graphic explaining how cyanobacteria is used to create organic fertilizer; Graphic sourced from Growponics

“The beauty of it is that there is zero waste. The old [cyanobacteria] cells that die go into an anaerobic biodigester. They’re broken down into two components: ammonia and methane gas (biogas). The methane gas is used to produce electricity through a generator, and may even produce extra electricity to sell back to the grid. The carbon dioxide from the generator exhaust is pumped straight back into the photobioreactor because the young cyanobacteria need it for photosynthesis. =The ammonia is converted into nitrates and combined with other elements sourced from mines to produce a complete organic fertilizer product”.

The company claims that the cyanobacteria are so efficient at producing biomass that the entire process is carbon-neutral or potentially even carbon-negative.

Scaling Up With The Help Of Partnerships

With expertise in building and operating high-tech automated greenhouses around the world including Israel and Guilford, Connecticut, Growponics has demonstrated success at the R&D stage.

Image sourced from Growponics

Growponics’ says their next biggest challenge is finding the right markets to test out their concept for an organic nitrogen-manufacturing cyanobacteria “factory.” They predict a full-scale venture could cost up to US$8M for a 5 hectare footprint producing 50 tonnes of pure nitrogen, or 910 m3 of 5% liquid fertilizer annually. Their financial projections based on the current market for organic fertilizer estimates an ROI of less than 3 years.

Hessel notes the vital role that basic scientific research funding played in the development of their work. “I have to thank the European community EIC and Horizon 2020 for having supported us. When private investors thought it was too far-fetched, they were the only people that actually supported the product. Now everyone is on board.”

Growponics also works closely with Dr. Sammy Boussiba at Ben Gurion University of the Negev on the underlying biological aspects of their work. Hessel credits him with saving years off the development of the technology.

Is This The Future Of Fertilizers?

Growponics may be on the brink of revolutionizing organic fertilizer production by harnessing natural biological processes to create a high-performing, soluble, organic, nitrogen fertilizer. Their work is directly contributing to the ongoing effort to drastically reduce carbon emissions, while helping to build sustainable and resilient systems for the future of agriculture.

About The Authors

Christian assists clients with the technical and supply chain aspects of their operations, bringing expertise in horticulture, plant genetics, and alternative food distribution models to Agritecture.

Expertise: sustainable field agriculture, molecular biology, regional food supply chains

.png)